We understand that every project is different. Our bespoke design and development services are tailored to your specific requirements and goals.

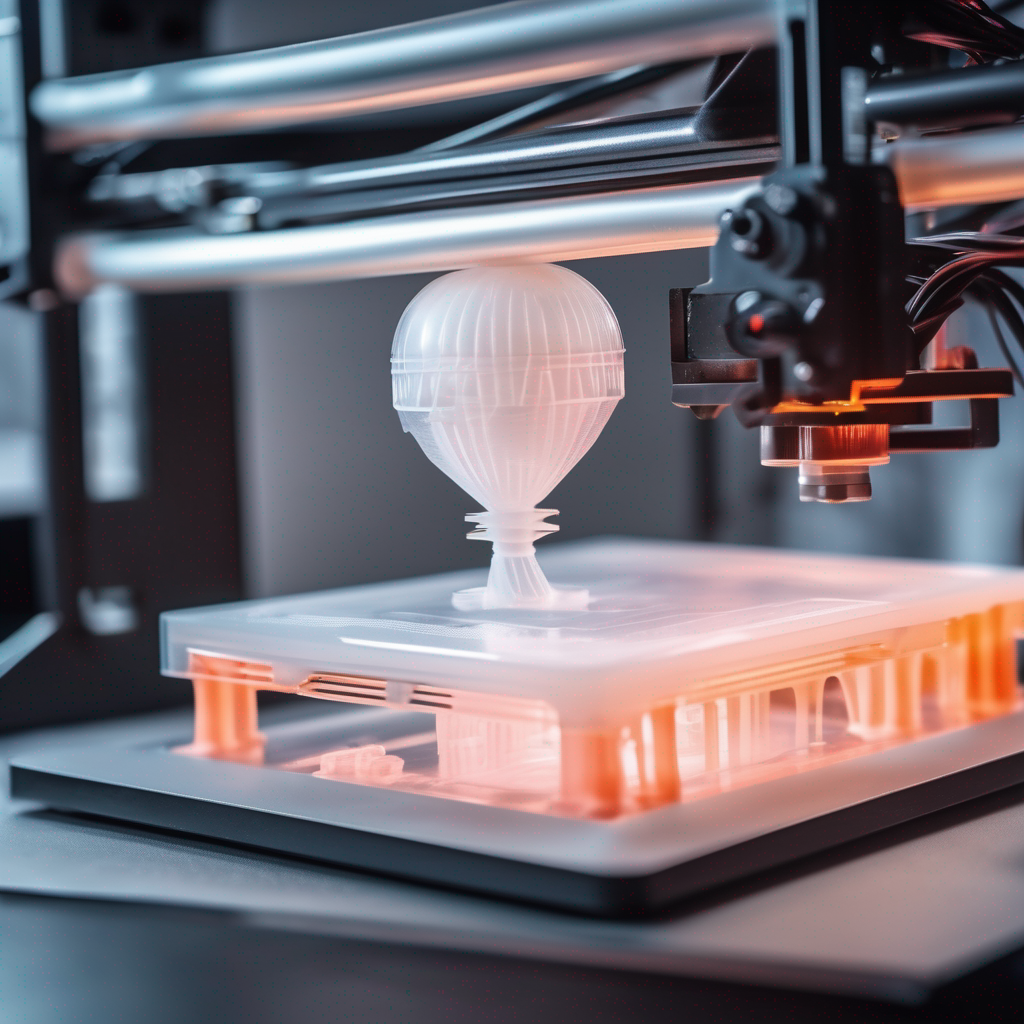

Our rapid prototyping service is designed to accelerate the development of your product ideas. By using cutting-edge 3D printing and CAD design technology, we bring your concepts to life quickly and efficiently. Whether you’re working on a functional prototype, custom parts, or iterative design solutions, we focus on precision and quality to ensure your prototype meets your exact specifications. Our process allows for rapid iterations, so you can test, refine, and perfect your design before moving into full-scale production. With a fast turnaround and cost-effective solutions, we help you bring your innovations to market faster.

Our CAD design service offers detailed and precise digital models tailored to your specific project needs. Whether you’re creating a prototype, custom part, or full product design, we use advanced CAD software to bring your ideas to life with accuracy and functionality. We work closely with you to understand your vision, ensuring that every design element is aligned with your goals. Our team provides design solutions that are optimized for manufacturability, ease of assembly, and performance. With our CAD expertise, we help you visualize your concepts, make informed decisions, and reduce errors before production begins.

Our project development service is designed to guide you from concept to completion with precision and efficiency. From initial ideas to final products, we combine expert CAD design, rapid prototyping, and 3D printing to streamline your development process. We collaborate closely with you to ensure every stage is tailored to meet your unique needs, whether it’s refining a design, testing functionality, or preparing for mass production. With fast iterations, cost-effective solutions, and a focus on quality, we help you bring your project to life, on time and on budget.

Our project development process is a collaborative journey, starting with a thorough consultation to understand your vision and requirements. We leverage industry-leading software like Autodesk and Fusion 360 for CAD design, ensuring precision and accuracy. For projects involving electronics, we partner with a leader in PCB and PCBA design, custom fabrication, and software development, providing a comprehensive solution. Once the design is finalized, we use rapid prototyping and 3D printing to create tangible prototypes for testing and refinement. Throughout this iterative process, we work closely with you, incorporating your feedback at each stage. Finally, we assist with preparing your design for manufacturing, ensuring a smooth transition to full-scale production. We believe in transparency and open communication, keeping you informed and involved every step of the way.

Rapid prototyping is a crucial part of our process. It allows us to quickly and cost-effectively create physical models of your designs, enabling you to visualize, test, and refine them early on. We primarily use Fused Deposition Modeling (FDM) for its versatility and speed. This minimizes the risk of costly mistakes later in the production process and allows for rapid iteration. The benefits include faster turnaround times, reduced development costs, and improved product quality. Because we have a team of engineers spanning software, manufacturing, and mechanical disciplines, we can seamlessly integrate rapid prototyping into every stage of the development process, ensuring efficient collaboration and problem-solving.

Our pricing is bespoke, tailored to the specific needs and complexity of each project. We understand that every project is unique, and we believe in providing customized solutions that fit your budget. We are committed to working with businesses of all sizes, from small companies (SMEs) and individual inventors to larger corporations. We encourage you to schedule an initial consultation with us. This allows us to understand your project requirements in detail and provide you with an accurate and competitive quote. We’re confident we can find a solution that meets both your needs and your budget.

We utilize a combination of high-end consumer 3D printers, chosen for their reliability and consistent performance, and custom-built 3D printers for specialized materials and unique project requirements. This allows us to accommodate a wide range of materials. While we can work with most commonly used 3D printing materials, we understand that some projects require specialized knowledge. If you have specific material needs, we can connect you with our in-house material scientist who can help you understand the properties of different materials and recommend the best option for your application.

We prioritize clear and consistent communication. We establish a dedicated point of contact for each project, ensuring you always have someone to reach out to. We utilize a variety of communication channels, including Google Meets for virtual meetings, phone calls for quick updates, and email for formal correspondence and file sharing. We regularly share update messages and images to keep our clients informed of progress and milestones. We actively solicit your feedback at every milestone and encourage open dialogue throughout the project lifecycle.

Project timelines vary depending on the complexity and scope of the work. While we always aim to deliver prototypes and finished products as quickly as possible, quality is paramount to us. We understand the importance of speed to market, but we never compromise on the quality of our work. We maintain open communication with our clients throughout the process, providing regular updates on timelines and project milestones. We work closely with you to establish realistic deadlines and strive to meet or exceed them, while ensuring the final product meets our high standards.

Yes, we can! We have experience working on projects for a diverse range of clients, from the automotive industry to the medical field, demonstrating our adaptability to different project needs. We can handle a wide range of project scopes and complexities. While we don’t currently offer CNC prototyping, we are actively working to add this capability to our services soon. We encourage you to contact us with the details of your project, no matter the size or complexity, and we will be happy to discuss how we can help bring your vision to life.

Quality is paramount to us. We have a rigorous quality control process tailored to the specific needs of each project. For physical products, we perform a number of visual inspections and precise measurements based on the client’s specifications. If any discrepancies or failures are identified at this stage, we immediately notify the client and re-run production to rectify any issues. For electronic projects, our quality control extends to the design of a dedicated test bench for the device. This test bench, which is also handed over to the client at the end of the project, allows for comprehensive testing of all aspects of the device, ensuring it functions as intended and meets all requirements.

Every project is unique.

Contact us for a tailored solution that meets your exact needs.